From the beginning of the design, INSPEED brake disc has focused on the important factors of high friction, thermal stability and durability, while also taking into account the high strength and lightweight of the brake disc, all from INSPEED innovative disc design and the application of new materials.

With a total of 72 ventilation grooves, heat can be exhausted efficiently. The brake thermal recession and brake failure problem has been weakened under the continuous high intensive braking.

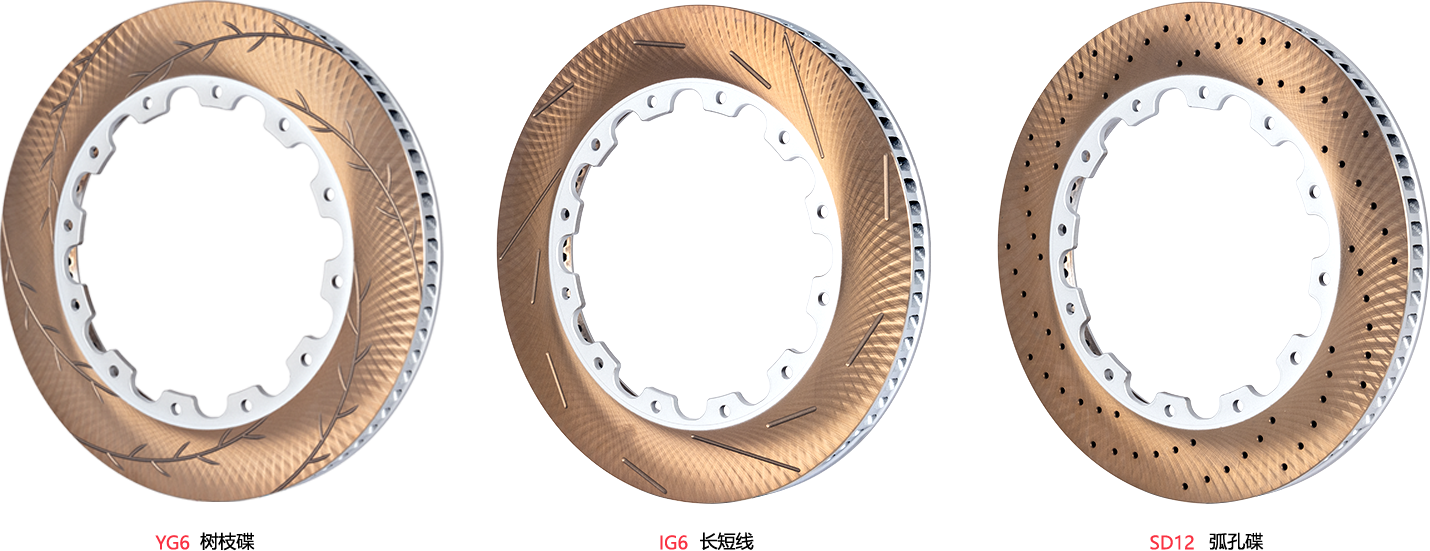

INSPEED BRAKE disc adopts new pattern designs, which can effectively reduce the thermal deformation.The brake disc has a better friction effect, while avoiding excessive wear of the brake pad, so as to have a long-term braking effect

The CARBON CONTENT is up to 3.83%, and the metal materials such as silicon and manganese are added to effectively improve the fatigue resistance of the brake disc, increase the wear resistance and reduce the braking noise.

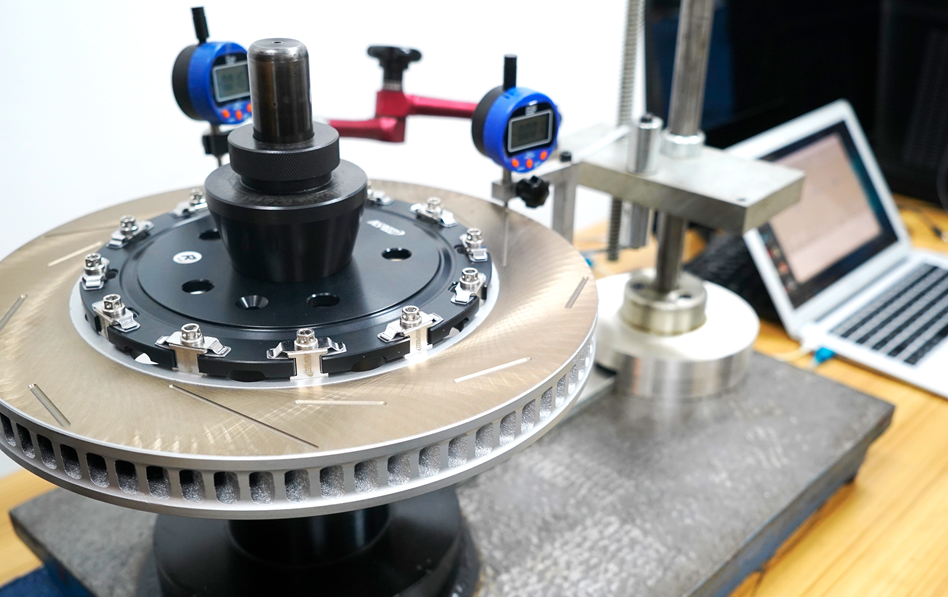

Fully floating design allows the friction surface of the brake disc to have a certain longitudinal expansion space in the case of overheating, and the brake performance is more stable under fully braking

After precision dynamic balance detection and DTV jitter detection, the stability of the brake disc can be ensured, and the driving jitter and brake jitter caused by the brake disc itself can be avoided

@INSPEED硬速制动

@INSPEED硬速轮毂

@Inspeed_Brakes

@Inspeed Brakes

@INSPEED硬速科技

@inspeed_brakes

Copyright © 2021 Copyright Inspeed Technology(shenzhen) Co.,Ltd

Filing No:粤ICP备2021114748号